MECHANICAL DESIGN

Our main area is the chemical engineering field and all related professional sectors and fields.

Thus, we undertake to prepare the following:

- Preparation of technology concept plans.

- Preparation of general layout plans, main assembly drawings, workshop drawings for production, on-site installations.

- Preparation of repair plans.

- Designing target machines.

- Design of individual machines, equipment, structures.

- Design of chemical and pharmaceutical equipment.

- Design of pressure vessels, equipment, storage tanks, performance of strength calculations according to ASME VIII. Div 1, (PED) according to EN-13445 and EN-14015.

- Design, manufacture, repair and voltage analysis of industrial piping systems and service steel structures, pipe racks, pipe bridges, and determination of maximum permissible voltages for the determination of the appropriate pipeline alignment.

- Design of heat generating equipment, energy review, we also undertake the design of boilers and fast steam generators.

- Perform thermal engineering calculations to determine the heat transfer surfaces of heat exchangers.

- Design of filtration systems.

- Solving complex tasks in the field of mechanical engineering.

- Sizing of various machines, equipment and structures.

- Sizing of steel structures covering the mechanical field.

- Fault mapping using advanced techniques (dFMEA, HOQ, FAST, value analysis, conceptual design methods, function analysis, QFD, 5why, Ishikawa, etc.).

- Create a layout.

- Reverse engineering: preparation of drawings of existing machines, equipment and structures.

- Redraw 2-dimensional drawings to 3-dimensional.

- Design of other special technologies.

- Solving innovation research and development tasks.

Our design software:

• SolidEdge with VEM modullal

• AutoCad

Technical calculations:

• MitCalc

Our company also undertakes flow, thermal and mechanical simulations carried out by our company with the help of an Ansys program.

Our engineering colleagues have the necessary qualifications and experience to perform these tasks, as well as membership of the Hungarian Chamber of Engineers.

Chamber privileges:

Design of chemical machines and equipment, pressure vessels, pipelines, pipelines: 05-1327 / GD-32 / GD-33

Mechanical engineering (facility and technology): 05-1327 / GP-T

Technical inspection of the construction of energy and hydrocarbon industrial buildings: 05-52207 / ME-EN

Responsible technical management for the construction of power supply structures: 05-52207 / MV-EN

With the help of our partner companies we have at our disposal: AxisVM, CAEPipe, Visual Vessel Design.

OUR REFERENCES

References in detail

- Column design

- FDFGK storage tank design

- High Pressure system design

- Filter System Design

- Mayfran Pressure Belt Filter pump station design

- Design of Mayfran SKF pumping station

- Design of Mayfran Daimler filter system

- Bangladesh heat exchanger design

- Mayfran ZF pump station design

- Preparation of decanter technical documentation

- Technical treatment of heat treatment cover

- Preparation of Ponsee Pump station construction plans

- Hydrocyclone design

- SPX, England, Filter Tank Design

- Bridgestone, Tatabánya: Design of glycol supply system and buffer tank

- Proctor & Gamble Zrt., Csömör – PVDF pipeline system design

Design of thermal equipment, technical consulting

- High pressure and temperature boiler technical advice

- Concrete kiln design, technical consulting

- Design of galvanizing furnace (Ócsa)

- Design of galvanizing furnace (Romania)

- Heat treatment furnace

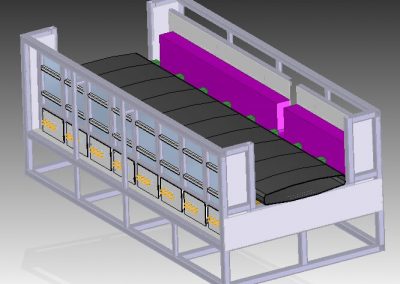

- Design and development of a pre-charring furnace for a carbon fibre production plant: development and design of a multi-zone kiln structure meeting technological parameters of the pre-charring furnace of the carbon fibre production plant, max. temperature 660°C.

- Design and development of carbon fibre production plant coalening furnace: development and design of the furnace structure of the carbon fibre production plant meeting technological parameters, max. temperature 1200°C.

- Design and development of a graphite furnace for a carbon fibre production plant: development and design of a furnace structure meeting technological parameters of the graphite production plant, max. temperature 2000°C.

Design of special purpose machines / equipment

- Screw conveyor design

- Design of a 6-axis CNC plasma cutter

- Sliding plug type door actuator design, technical consulting

- Design of spiral tube making equipment

- Hydraulic lifting table design

- Concrete kiln design

- Design of a target ball removal machine

Design of tanks, containers, steel structures

- Storage tank, filter, static design of steel structures, technical expertise

- PVC silo tank design

- Design of horizontal storage tanks

- Mixer tank design

- Hot water storage tank design

- Design of Kronospan GmbH, Germany (Bischweier) Fire protection silo, PZ storage silo and Wood chip storage silo

- BIS Hungary Kft: preparation of ISD Dunaferr, PE tank construction permit documentation

- Pannergy Kft.: design of a 40 m3 deaerator and a 100 m3 water tank

- Collapsible container design

- Velux Ltd.:, Storage tank roof structure modification

- Perlin Project steel structure design

- Slide structure for cutting equipment

- Scaffold design